1300 degree touch screen muffle furnace series

High temperature box furnace

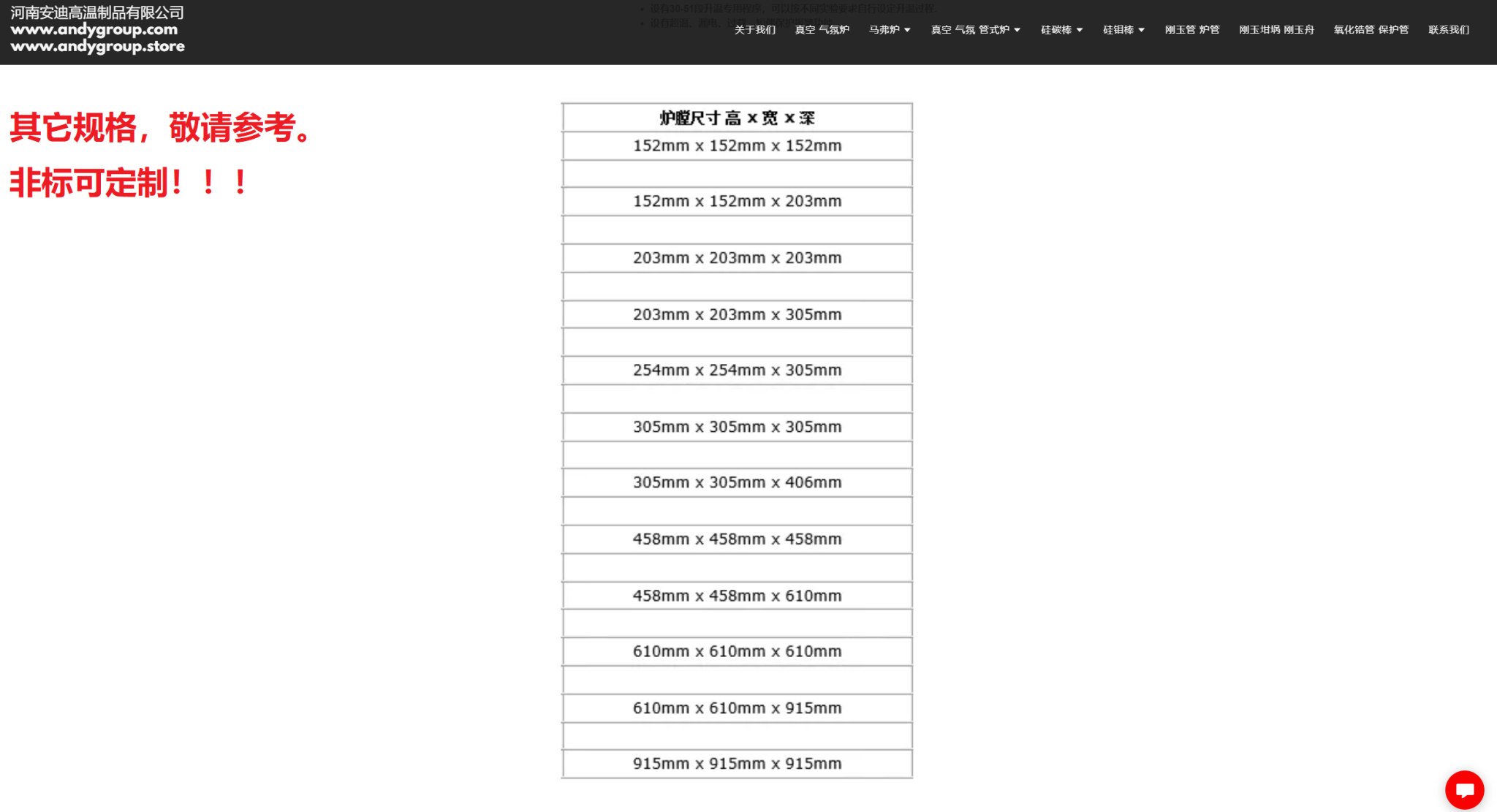

Model number | Furnace size; High x Width x; Deep | Maximum temperature; (C) | Continuous furnace temperature (C) |

AY-BF-161620-130 | 400mm x 400mm x 500mm | 1300 | ≤1200 ℃ |

Product model | AY-BF-161620-130 |

Product Introduction | This style of box furnace uses 1500 ℃ silicon carbon rods as heating elements, with 30-51 stage programmed temperature control, and a maximum temperature of 1300 ℃. Rated temperature: 1200 ℃, using S-type dual platinum rhodium thermocouple for temperature measurement and automatic temperature control, with high temperature control accuracy (1 ℃). This furnace has the advantages of high operating temperature, high-precision temperature control, simple operation, and convenient maintenance, and can be widely used in metallurgy, machinery, light industry, commercial inspection, higher education institutions, and scientific research departments. |

Main features | 1. 1500 ℃ silicon carbide rod heating |

Technical parameters | 1. Heating element: 1500 ℃ silicon carbide rod |

1300 degree energy-saving muffle furnace series

High temperature box furnace

Model number | Furnace size; High x Width x; Deep | Maximum temperature; (C) | Continuous furnace temperature (C) |

AY-BF-161620-130 | 400mm x 400mm x 500mm | 1300 | ≤1200 ℃ |

Product model | AY-BF-161620-130 | ||||||||||||||||||

Product Introduction | This style of box furnace uses 1500 ℃ silicon carbon rods as heating elements, with 30-51 stage programmed temperature control, and a maximum temperature of 1300 ℃. Rated temperature: 1200 ℃, using S-type dual platinum rhodium thermocouple for temperature measurement and automatic temperature control, with high temperature control accuracy (1 ℃). This furnace has the advantages of high operating temperature, high-precision temperature control, simple operation, and convenient maintenance, and can be widely used in metallurgy, machinery, light industry, commercial inspection, higher education institutions, and scientific research departments. | ||||||||||||||||||

Main features | 1. 1500 ℃ silicon carbide rod heating | ||||||||||||||||||

Technical parameters | 1. Heating element: 1500 ℃ silicon carbide rod High temperature box furnace Intelligent box type high-temperature furnace,Adopting modern high-tech technology, the shell is processed by advanced CNC machine tools, luxurious and beautiful electrostatic spray painting technology, and the furnace is made of special lightweight materials. All indicators have reached the international advanced level and are widely used in laboratories such as coal, electricity, metallurgy, chemical engineering, as well as laboratory analysis and industrial heat treatment in colleges and universities. Characteristics:①The integrated design of the furnace body and intelligent controller makes the entire furnace shape beautiful and elegant; ②The heating element adopts a double-sided lining plate with fast heating speed, uniform temperature, easy replacement, and reliability③The furnace is made of advanced lightweight materials, which reduces the weight compared to traditional muffle furnacesThe heating rate has increased;④Adopting a brand new digital instrument and intelligent temperature control, it can reduce visual reading and human operation errors, greatly improving work efficiency; ⑤Equipped with multiple protection functions, it improves safety and reliability. Function: Equipped with a 30-51 stage heating dedicated program, the heating process can be set according to different experimental requirements; Equipped with over temperature, leakage, overload, and short-circuit protection alarm functions.

|

Online Service

Online Service